|

Ningguo Dongfang Wear-Resistant Material Co.,Ltd

|

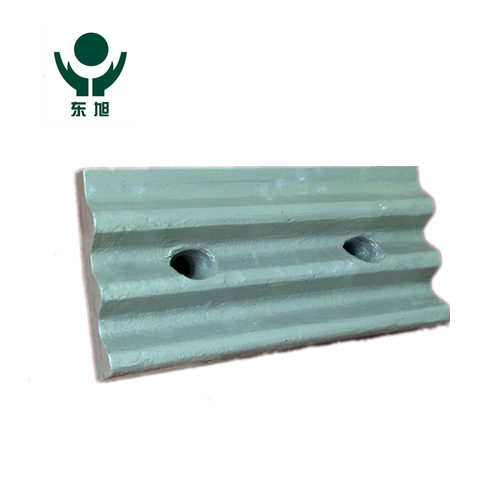

high performance groove alloy liner

| Payment Terms: | T/T,L/C |

| Place of Origin: | Anhui, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.high performance groove alloy liner for ball mill

2.customised product

3.assured quality for long-term use

4.fast delivery

Description of high performance groove alloy liner

1.Brief introduction

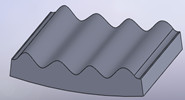

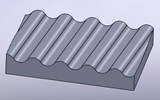

The groove liner surface consists of many arcs, linear cambered liner is used for the 1st compartment and Spiral

cambered liner for the 2nd and 3rd compartment.These cambered radius do not change according to the mill

diameter,but with the ball diameter,approximately ranging from R25 to 55mm. Grinding balls contact liners with

arc surface, and the contact arc length is 1/4~1/3 circumference of balls, and contact arc reaches 120°.Compared

to the point contact, the contact area (grinding area) is a few times larger. Therefore, the volume of the entire mill

grinding expanded dozens of times, greatly improved production efficiency.

2.Linear cambered liner & Spiral cambered liner & sectional view as follows

3.Picture of the groove alloy liner for ball mill

4.Key benefits of groove alloy liner

1.Grinding mill working efficiency improves 8%-30%.

2.Power consumption of unit output reduce by 10%-35%.

3.Grinding media consumption of unit output reduce by 15%-30%.

4. Liner lifetime increase by 2-5 times.

5. Noise of grinding mill reduce by 5-10dB.

5.Brand strength to witness

Shipment

1.Usually we ship your order by sea.

2.We'll tell you the shipping status once your order has been sent.

Payment:

We accept T/T, L/C.etc. 30% advanced payment, 70% before loading.

We sincerely welcome customers from all over the world to come to negotiate business with us. We are sure to provide our best service to you.